POSCO Gwangyang Steelworks in collaboration with GIFT achieved ‘Automated basic oxygen furnace (BOF)…

페이지 정보

작성자 최고관리자

댓글 0건 조회 734회 작성일 2021-08-26 17:23

본문

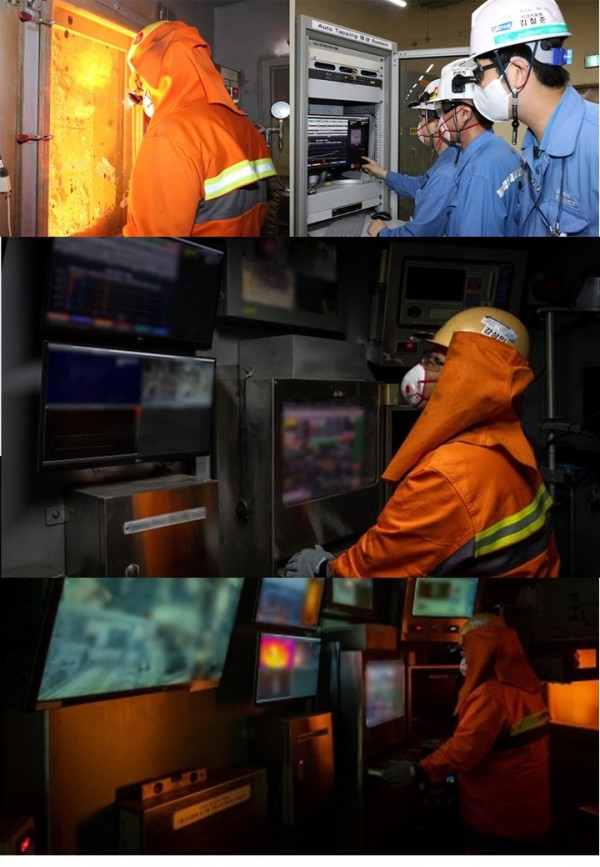

POSCO Gwangyang Steelworks announced that it has taken the first step toward realizing a smart factory in the steelmaking sector by developing an automated basic oxygen furnace(BOF) tapping system using artificial intelligence (AI).

This automated basic oxygen furnace(BOF) tapping system is attracting attention in that it achieved it with POSCO's own technology from the beginning without relying on external technology.

Steel tapping is a process in which molten iron that has undergone the removal of impurities is placed in a transfer container. During tapping, there was a problem that the quality was different because there were variations for each worker, such as the timing of input of ferroalloy for adjusting the oxygen and components of the molten metal and the timing of the completion of tapping.

To solve this problem, the steelmaking department of Gwangyang Steelworks collaborated with the POSCO Research Institute, Electrical Technology Section, POSCO ICT, and POSTECH GIFT.

First, the task was subdivided into stages, and data by condition were collected and standardized. Afterwards, a basic oxygen furnace (BOF) tapping systempattern was derived, and based on this, automated attendance was implemented.

Based on this, Gwangyang Steelworks not only improved work efficiency and stabilized quality, but also greatly improved worker safety.

In the 2nd steel mill where the steel tapping automation is applied, it is possible to automatically control the tapping facilities with the push of a button, and through AI image recognition technology, it is possible to detect the danger caused by high-temperature work without directly checking the tapping process.

An official from Gwangyang Works said, "We plan to further advance the automated basic oxygen furnace(BOF) tapping algorithm and develop AI image recognition technology to implement automatic control of all risks that may occur during the steel tapping process. We will greatly reduce the risk of safety accidents for workers.”

- 이전글Prof. Youn-Bae Kang awarded the 2021 The Korean Institute of Metals and Materials Dong Seok Yoon Award 21.10.27

- 다음글POSTECH GIFT ranked 12th in the world in the Metallurgical Engineering category in the 2021 Academic Ranking of World Universities (ARWU). 21.07.20

댓글목록

등록된 댓글이 없습니다.